Central Criminal Court

The Central Criminal Court for England and Wales, also known as the Old Bailey, has undertaken a major ten-year £43 million modernisation plan to refurbish the building and its services.

A key part of the refurbishment has been the replacement of its giant 1967 11MW of Netherton oil-fired steam boilers with high efficiency Remeha Gas 610 Eco Pro Gas condensing boilers.

Arguably the most famous criminal court in the world since its reconstruction in 1907, today the Central Criminal Court is managed by the City of London Corporation. For the last 50 years, the building, which houses 18 courts and 52 cells over three floors, has relied on four ornate steam boilers for its heating and air conditioning. The age of the boilers and the growing difficulty in sourcing spare parts made it essential to refurbish the heating service. The City of London Corporation’s prime concerns were twofold:

- To achieve more sustainable operation through improved energy performance

- Reduce building emissions in line with its strategy for improved air quality within the Square Mile.

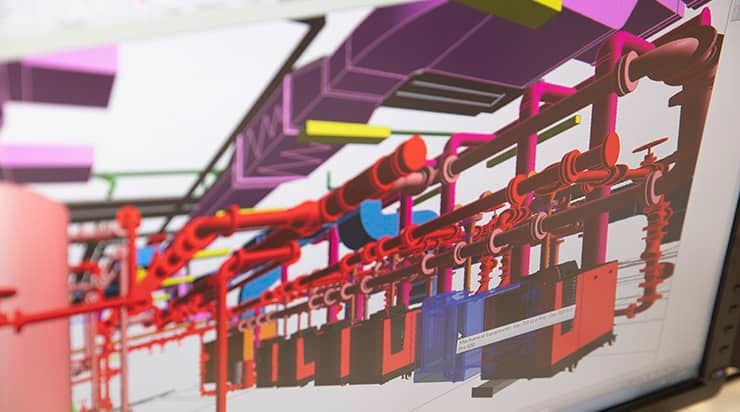

M&E consultants AECOM recommended replacing the four steam boilers with seven Remeha Gas 610 Eco Pro boilers in a four-phase installation programme.

Richard Morgan, Associate Director at AECOM, said: “The Remeha boilers ticked all boxes for the City of London Corporation, combining exceptional high efficiencies."

The Central Criminal Court handles around 1,500 of Britain’s most serious criminal cases a year with each court holding two sittings daily. Planning the full works programme was a lengthy process as the Central Criminal Court must remain available for court sittings throughout the refurbishment scheme.

Richard continued: “To avoid disrupting trials, the entire refurbishment project has had to be planned as a live changeover. It’s been a real feat of logistic engineering.”

The decision was taken to install the new boilers in the original 1907 coal boiler room in a parallel installation to the steam boilers in the second plant room. The two Gas 610-1300 Eco Pro boilers and one Gas 610-860 Eco Pro have been installed in a modular arrangement to maximise heating reliability and security for a more comfortable environment. At the same time, the configuration makes full use of the boilers’ modulating feature for more accurate matching of heat demand – increasing overall system efficiency and reducing energy waste.

Refurbishing a Grade II-listed building like the Old Bailey required careful planning to avoid any alterations to its fabric. Here again the design of the Remeha boilers proved helpful.

“The Remeha 610s are not only compact but they can be dismantled into parts,” added Richard. “This was a real benefit as it made access to the basement plant room much quicker and easier. Once they were inside the plant room, it was simply a matter of reassembling and positioning them.”

With the three Remeha boilers connected and serving the Low Temperature Hot Water (LTHW) radiator system throughout the building, Phase One of the services upgrade is now complete. The four additional Gas 610 Eco Pro boilers will be installed in the next few years to complete the heating refurbishment, with the entire project scheduled for completion in 2023.

Our Solutions

Find out more about our energy efficient heating products.

Related Articles

Historic Buildings

Alton Castle

Historic Buildings

Queen Elizabeth's Hospital School

Education

Leeds Beckett University

Education

Archbishop Ilsley School

About Remeha

Our dedicated experts and comprehensive project approach support you from concept to commission to achieve your project goals.